Ibhodi elinamabala anemibala liyimpahla yokwakha eluhlaza futhi evumelana nemvelo. Indlela yokuyikhetha kahle, ukuyisebenzisa ngokunengqondo, nokuthuthukisa impilo yayo yesevisi kuyindaba ethinteka kakhulu kubanikazi nabakhi bonjiniyela. I-Baosteel, njengemboni yensimbi enenqubo egcwele, inokuhlangenwe nakho okucebile ekukhiqizeni nasekusetshenzisweni kwamapuleti ahlanganiswe ngombala. Imojula "Yokukhetha Okubalulekile Kwesayensi" inikeza isincomo esifushane nesingeniso kubasebenzisi ekukhetheni nasekusetshenzisweni kwamapuleti anemibala.

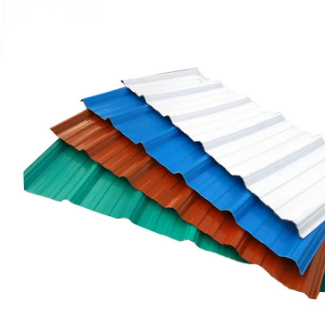

Ukukhethwa okulungile kwamaphaneli ahlanganiswe ngombala kufanele kucabangele indawo yemvelo, indawo yokusetshenziswa, impilo yedizayini, nezici zesakhiwo sesakhiwo, ukuze kukhethwe uhlobo lwensimbi, ukucaciswa, ukunamathela, nokunamathiswa okuhambisana naso. Abaklami bezakhiwo, abanikazi bonjiniyela, nabacubungulayo bacabangela ukusebenza kokuphepha (ukumelana nomthelela, ukumelana nokuzamazama komhlaba, ukumelana nomlilo, ukumelana nomfutho womoya, ukumelana neqhwa), ukusebenza kwendawo yokuhlala (ukuvikela amanzi, ukugqunywa komsindo, ukwahlukanisa), ukuqina (ukumelana nokungcola, ukuqina, ukugcinwa kokubukeka) , kanye nomnotho (izindleko eziphansi, ukucubungula kalula, ukunakekelwa okulula, nokushintshwa kalula) kwezakhiwo. Kubahlinzeki bamapuleti ensimbi anombala, lezi zakhiwo kufanele ziguqulwe zibe izakhiwo zepuleti lensimbi elinombala ngezigayo zensimbi futhi ziqinisekiswe. Izidingo zokusebenza zamapuleti ensimbi ahlanganiswe ngombala ikakhulukazi zifaka izici zomshini zento esetshenziswayo (amandla aqinile, amandla esivuno, ukwelula), ukusebenza kokunamathela (uhlobo lokumboza, ukujiya kokunamathela, nokunamathela kokunamathela), nokusebenza kokunamathela (uhlobo lokunamathela, umbala, isicwebezelisi , ukuqina, ukuqhubekela phambili, njll.). Phakathi kwakho, ukumelana komoya, ukumelana nomthelela, ukumelana neqhwa, ukumelana nokuzamazama komhlaba, njll. konke kuhlobene nezakhiwo zemishini yezinto zokwakha, futhi vele, zihlobene nokuma kwamagagasi, ukushuba, ubude besikhathi, kanye nesikhala samapuleti ensimbi anombala. . Uma amapuleti ensimbi anombala afanele akhethiwe futhi ahlanganiswe nomklamo wepuleti lensimbi onephrofayili efanele, angeke nje ahlangabezane nesici sokuphepha sezakhiwo kodwa futhi anciphise izindleko zobunjiniyela. Ukuqina, ukusebenza kokucubungula, nokugcinwa kokubukeka kwezinto kunqunywa kakhulu ukuqina kwezingubo zokumboza.

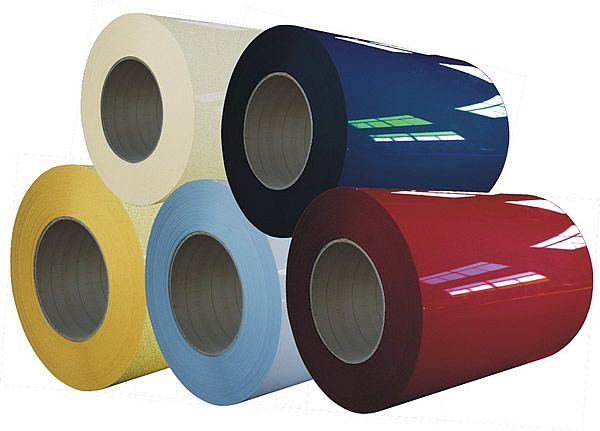

Izinhlobonhlobo zokugqoka

Njengamanje, izinhlobo zezingubo ezisetshenziselwa amapuleti ensimbi anombala zifaka i-polyester coating (PE), i-fluorocarbon coating (PVDF), i-silicon modified coating (SMP), i-high weather resistance (HDP), i-acrylic acid coating, i-polyurethane coating (PU) , i-plastic sol coating (PVC), njll.

I-polyester evamile (i-PE, i-Polyester)

I-PE enamathelayo inokunamathela okuhle ezintweni, futhi amapuleti ensimbi anombala kulula ukuwacubungula futhi akhe, angabizi kakhulu, futhi anezinhlobonhlobo zemikhiqizo. Kukhona anhlobonhlobo ongakhetha for umbala kanye isicwebezelisi. Ngaphansi kokuchayeka okuqondile ezindaweni ezijwayelekile, impilo yayo yokunqanda ukugqwala ingafinyelela eminyakeni engu-7-8. Kodwa-ke, ezindaweni zezimboni noma ezindaweni ezingcoliswe kakhulu, impilo yayo yesevisi izoncishiswa uma kuqhathaniswa. Kodwa-ke, ukumbozwa kwe-polyester akufanelekile ukumelana ne-UV kanye nokumelana ne-powdering yefilimu. Ngakho-ke, ukusetshenziswa kwezingubo ze-PE kusadingeka kunqunyelwe, futhi ngokuvamile zisetshenziswa ezindaweni ezinokungcoliswa komoya okuncane kakhulu noma imikhiqizo edinga ukubunjwa okuningi nokucutshungulwa.

I-Silicone Modified Polyester (SMP)

Ngenxa yokuba khona kwamaqembu asebenzayo - OH/- COOH ku-polyester, kulula ukusabela namanye ama-polymers nezinto. Ukuze kuthuthukiswe ukumelana nokukhanya kwelanga kanye ne-pulverization ye-PE, i-silicone resin enokugcinwa okuhle kombala nokumelana nokushisa isetshenziselwa ukusabela kwe-denaturation. Isilinganiso se-denaturation ne-PE singaba phakathi kuka-5% no-50%. I-SMP inikeza ukuqina okungcono kwamapuleti ensimbi, anempilo yokumelana nokugqwala okufika eminyakeni eyi-10-12. Yiqiniso, intengo yayo nayo iphakeme kunaleyo ye-PE, Nokho, ngenxa yokunamathela okungagculisi nokucubungula ukwakheka kwe-Silicone resin ezintweni, amapuleti ensimbi ahlanganiswe ngombala we-SMP awafanele izimo ezidinga izinqubo eziningi zokubumba, futhi asetshenziselwa kakhulu ukwakha uphahla nezindonga zangaphandle.

I-polyester engamelana nesimo sezulu esiphezulu (i-HDP, i-polyester ehlala isikhathi eside)

Mayelana nokushiyeka kwe-PE ne-SMP, inkampani yaseBrithani i-HYDRA (manje etholwe yi-BASF) kanye nenkampani yaseSweden i-BECKER yathuthukisa i-HDP polyester coatings ekuqaleni kuka-2000 engafinyelela ukumelana nesimo sezulu esingu-60-80% ku-PVDF, futhi iphakeme kune-silicon evamile ye-polyester eguquliwe. . Ukumelana kwazo nesimo sezulu sangaphandle kufinyelela eminyakeni eyi-15. I-polyester resin emelana nesimo sezulu esiphezulu ihlanganiswa kusetshenziswa ama-monomers aqukethe isakhiwo se-cyclohexane ukuze kuzuzwe ibhalansi phakathi kokuguquguquka, ukumelana nesimo sezulu, kanye nezindleko. Ama-polyols amahhala nama-asidi anephunga elimnandi asetshenziselwa ukunciphisa ukumuncwa kokukhanya kwe-UV ngenhlaka, kuzuzwe ukumelana nesimo sezulu esiphezulu sokumbozwa. Ukwengezwa kwama-absorber ultraviolet kanye ne-steric hindrance amines (HALS) kufomula yokugqoka kuthuthukisa ukumelana nesimo sezulu sefilimu kapende. Ikhoyili ye-polyester imelana nesimo sezulu esiphezulu ibonwe yimakethe phesheya, futhi ukuphumelela kwayo kwezindleko kuvelele kakhulu.

I-PVC Plastisol

I-PVC resin inokumelana okuhle kwamanzi nokumelana namakhemikhali, futhi ngokuvamile imbozwe ngokuqukethwe okuqinile okuphezulu, enogqinsi oluyi-100-300 μ Phakathi kwe-m, ingahlinzeka nge-PVC enamathelayo ebushelelezi noma ukwelashwa okugqamile okukhanyayo njenge-embossing coating; Ngenxa yokuthi i-PVC enamathela iyinhlaka ye-thermoplastic enogqinsi oluphakeme lwefilimu, inganikeza ukuvikeleka okuhle kwamapuleti ensimbi. Kodwa i-PVC inokumelana nokushisa okubuthakathaka. Ezinsukwini zokuqala, yayisetshenziswa kakhulu eYurophu, kodwa ngenxa yezindawo zayo ezingezinhle zemvelo, okwamanje isetshenziswa kancane kancane.

I-PVDF i-fluorocarbon

Ngenxa yamandla okubopha okuqinile phakathi kwamabhondi amakhemikhali e-PVDF, ukunamathela kunokumelana nokugqwala okuhle kakhulu nokugcina umbala. Ingumkhiqizo othuthuke kakhulu embonini yezokwakha onamapuleti ensimbi ahlanganiswe ngombala, onesisindo samangqamuzana amakhulu kanye nesakhiwo sebhondi eqondile. Ngakho-ke, ngaphezu kokumelana namakhemikhali, izakhiwo zemishini, ukumelana kwe-UV, nokumelana nokushisa nakho kubalulekile

Ukukhethwa kwe-primer, kunezici ezimbili ezibaluleke kakhulu. Enye iwukucabangela ukunamathela phakathi kwe-primer ne-topcoat, kanye ne-substrate. Okunye ukuthi i-primer inikeza iningi lokumelana nokugqwala kwe-coating. Kusukela kulo mbono, i-epoxy resin iyisinqumo esingcono kakhulu. Uma kucatshangelwa ukuguquguquka nokumelana ne-UV, i-polyurethane primer nayo ingakhethwa.

Ukuze uthole i-back coat, ukukhetha okulungile kakhulu ukukhetha uhlaka lwezingqimba ezimbili, okungukuthi ungqimba olulodwa lwe-primer yangemuva kanye nesendlalelo esisodwa se-back topcoat, uma ipuleti lensimbi eliboshwe ngombala lisesimweni sebhodi elilodwa. I-primer kanye nangaphambili ziyizinhlobonhlobo ezifanayo, futhi ijazi eliphezulu kufanele libe nombala okhanyayo (njengomhlophe) i-polyester. Uma ipuleti lensimbi elifakwe umbala lisesimweni esiyinhlanganisela noma isangweji, kwanele ukusebenzisa ungqimba lwe-epoxy resin ene-adhesion enhle kakhulu kanye nokumelana nokugqwala ngemuva.

Njengamanje, kunezinhlobo eziningi zamapuleti ensimbi ahlanganiswe ngombala osebenzayo, njenge-antibacterial color coating, i-anti-static color coating, i-thermal insulation color coating, i-self-clean color coating, njll. Ukuthuthukiswa kwale mikhiqizo kuhloswe ngayo ukuhlangabezana nezidingo ezikhethekile ze abasebenzisi, kodwa ngezinye izikhathi akwenzeki ukulinganisa ukusebenza kwemikhiqizo enamabala anemibala. Ngakho-ke, lapho abasebenzisi bekhetha amapuleti ensimbi anombala osebenzayo, kufanele bacace ngezidingo zabo zangempela.

Isikhathi sokuthumela: Sep-18-2023